OUR MANUFACTURING FACILITIES ARE SPREAD IN 47 ACRES OF GREEN ENVIRONMENT ACROSS THREE LOCATIONS.

- Maheshwaram Unit I – in 7 acres – has a completely advanced, European up for its manufacturing process. (Certifications – BRC – IOP, ISO 9001 : 2008, ISO 14001)

- Burgul Unit III – Burgul Village, Farooqnagar Mandal, Mahaboobnagar District. in 40 acres.

ROTOGRAVURE PRINTING

Designed to meet the international standards in cleanliness and hygiene, the unit is equipped to even meet the stringent norms for safety, health and environment stipulated by the Food and Pharma industries.

To maintain uniformity, the shop-floor is completely equipped with Positive Pressure System. This ensures that production is carried out in a dust and insect free environment. Additionally, a stringent Pest Control System makes the units absolutely pests free.

With the above being achieved and practiced, the unit is certified as ISO 9001: 2008 and BRC-IOP

DOCTORING

We are equipped with high speed doctoring machines, which can remove printing flaws ensuring there are ‘zero’ defects in the final product

EXTRUSION LAMINATION

We have installed an Extrusion lamination facility with an installed capacity of 3600 MT pa. This has helped us to develop and capture requirements of different industries such as Snacks, Pharma etc

1 Extrusion Lamination machine from Hui-Long, China

Max width around 1200 mm

Majorly catering to the snacks industry

Helps maintain flexibility in

the film

Very low chance of de lamination problem

ADHESIVE LAMINATION

We have 8 lamination machines with both solvent free and solvent based lamination facilities which help us to meet the requirements of various industries. Solvent free lamination ensures that the packaged product is safe for consumption.

5 Solvent free lamination machines, Nord

Meccanica, Italy

2 Super-combi machines from Nord Meccanica, Italy

1 solvent based Indian machine

Width up to 1320 mm

SLITTING

High quality slitting machines ensure that the coils are wound properly and are free to use on

the FFS machines.

12 high speed Slitting machines

Speeds up to 600 meters per minute

Facility of both PVC and Paper Cores as per the requirement

Special slitters for paper upto 1000mm Diameter

POUCHING

Branding is a decisive factor in the success of any product. Pouches of various types offer a different dimension to branding.

11 pouch making machines

A High speed pouch making machine from TOTANI, Japan

Customized pouches such as Centre Sealed, Side Sealed, Side Gusset, Stand-up , Reusable and Pouches with Zip Lock, V – Notch, Soft Corners, Hanger Hole, Loop, Euro hole, etc..

IN OUR 40 ACRES NEW MANUFACTURING PLANT IN MANDAL,

MAHABOOBNAGAR DISGTRICT

Intelligent design

Enhanced print accurate spindle positioning and servo drives provide the highest register accuracy.

Improved ease of use

Effective set-up, monitoring, and maintenance with minimum downtime. An example of improved ease of use is a lightweight 2-module chamber doctor blade, featuring an outsanding smooth and quality printing.

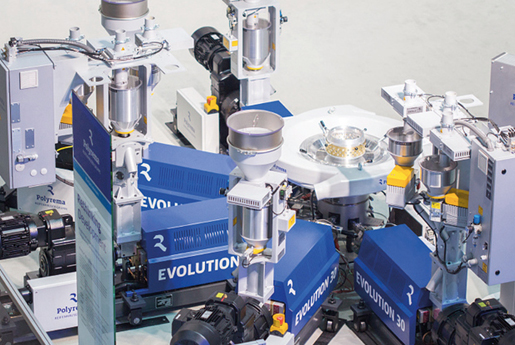

BLOWN FILM PRODUCTION

3 LAYERS COEX

7 layer HIGH BARRIER systems with Ultra Fusion technologies increasing the product quality. This technology is unique on the market.

COEX FLEX® 5

Lines for 5 layer barrier film

5 layer co- extrusion High Barrier film with compact die heads, increasing the quality of the film produced.

Spout and Shape Pouches from China by Dec 2015

Laser Scoring March 2016

Extrusion Lamination from Hui-Long, China with a capacity of 400 Tons per month

Hot Melt Coating of 400 Tons Per Month – June 2016

A dedicated R&D lab with new equipment designed to assist clients in evaluating various packaging material – December 2015